SAFE SUSPENSION AND MOVEMENT: SOLUTIONS FOR MODERN CARS

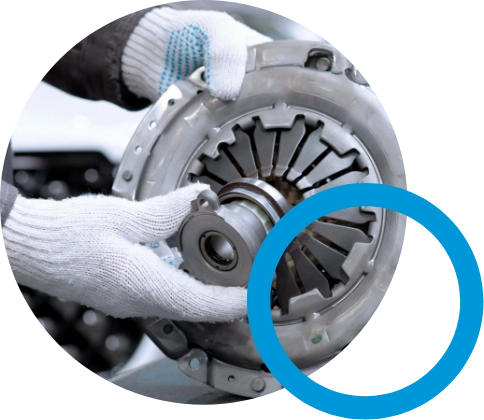

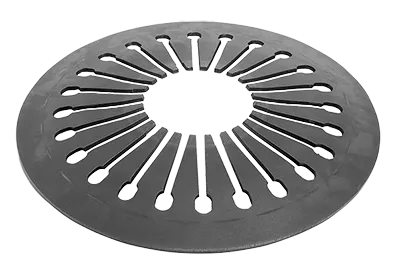

You drive better with experience. The first European disc spring clutch, the cornerstone of all of today’s vehicle dry clutches, was invented by us. The “HÄUSSERMANN clutch” is known worldwide under the brand name LuK (Lamellen und Kupplungsbau August Häussermann). We have been one of the leading engineering partners in the automotive sector for more than 95 years.

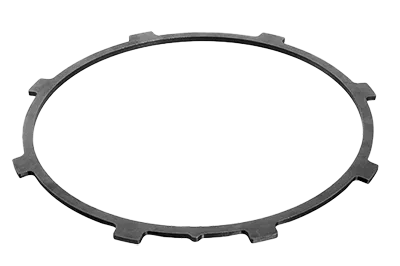

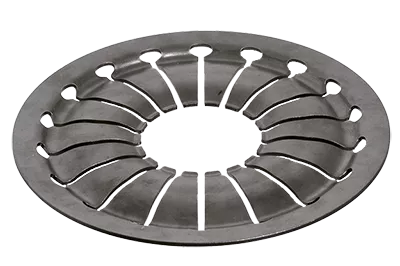

Our high-performance solutions, individually designed to meet specific requirements, are used in the drive train, chassis and comfort and safety systems of renowned automobile brands, from the largest automotive manufacturers (OEMs) to suppliers (first tiers) and the spare parts sector. The IATF 16949 certified products meet the highest automotive standards thanks to the variable characteristic curve design with installation space and weight-optimized design, high radial stiffness and permanently safe function.

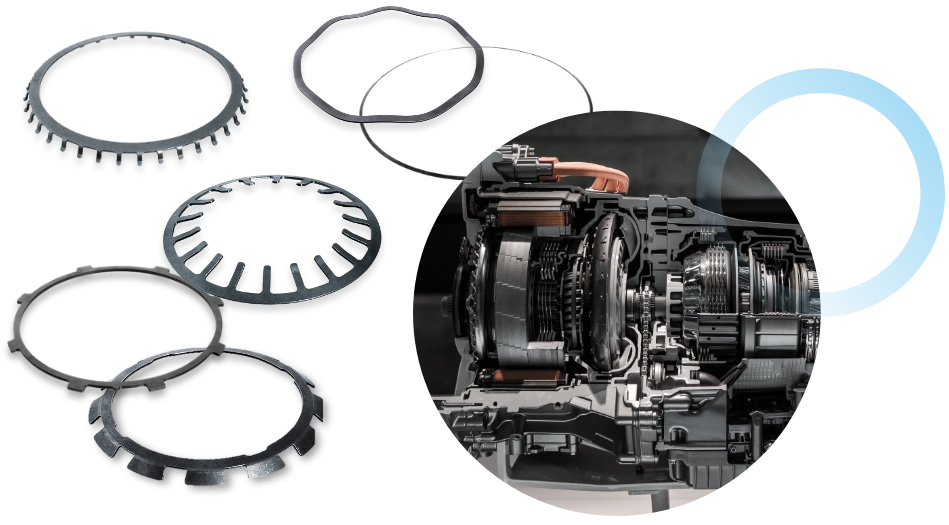

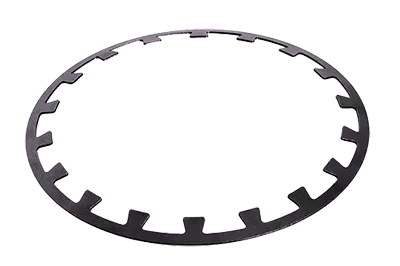

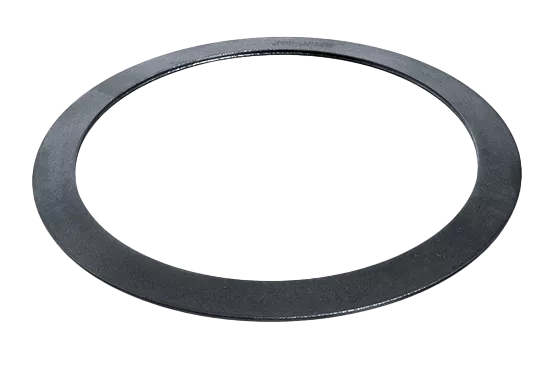

Our product range includes high-end disc springs, disc spring columns, customized special solutions, diaphragm springs / pressure plates, slotted springs, wave springs, separating springs, deep-drawn parts / heat shields, hot-formed punched and bent parts made of spring steel, and other components.