We offer customers from tool construction and mechanical engineering certified high-end quality and application-specific solutions developed in dialogue. From the initial inquiry to engineering, project management, prototyping, single-item production to series production with batch sizes in the millions. Worldwide with flexible logistics management and reliable spare parts provision.

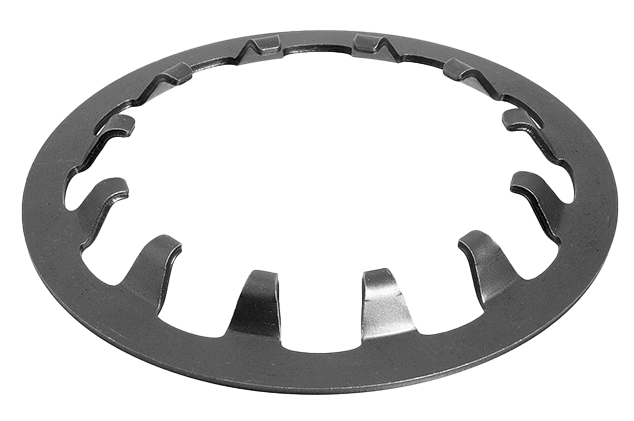

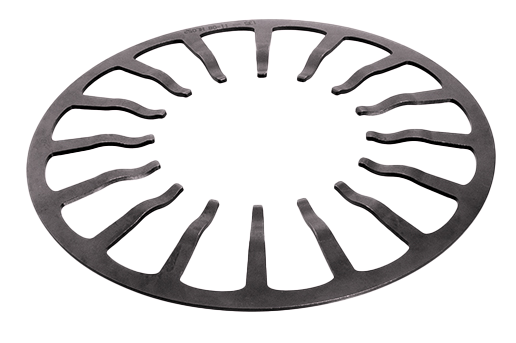

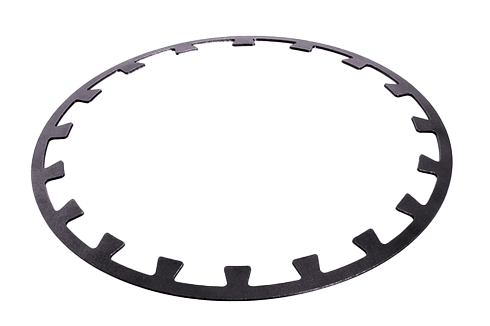

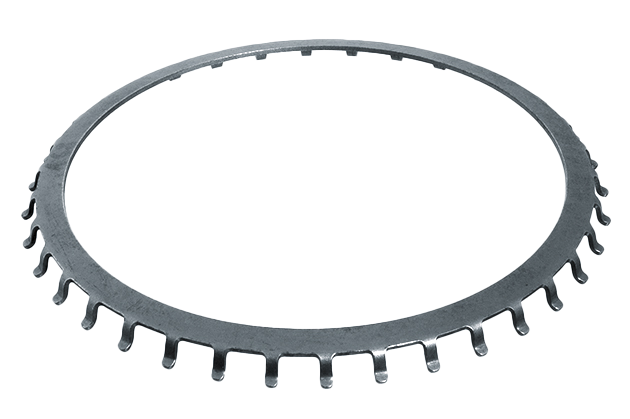

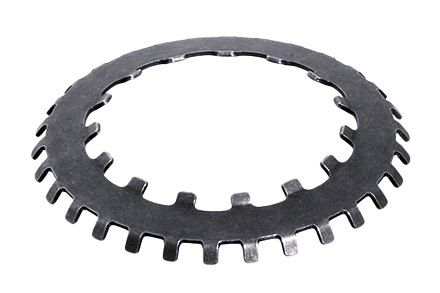

At HÄUSSERMANN, disc springs, wave springs and other product solutions are exclusively tailored to the specifications and requirements of all types of high-end machine tools. Quality far exceeds the DIN specifications. It enables a free design of motor spindles and other machine components. Perfect damping for narrow manufacturing tolerances and smooth running is achieved. Our products and solutions ensure secure, highly precise machining and processing, long machine run times without interruption and reduced maintenance costs. Likewise, the assembly effort of solutions can be significantly simplified and reduced (e.g. specific disc spring for preloading ball bearings).