A lot of pressure in a small space: Wave springs hold their own

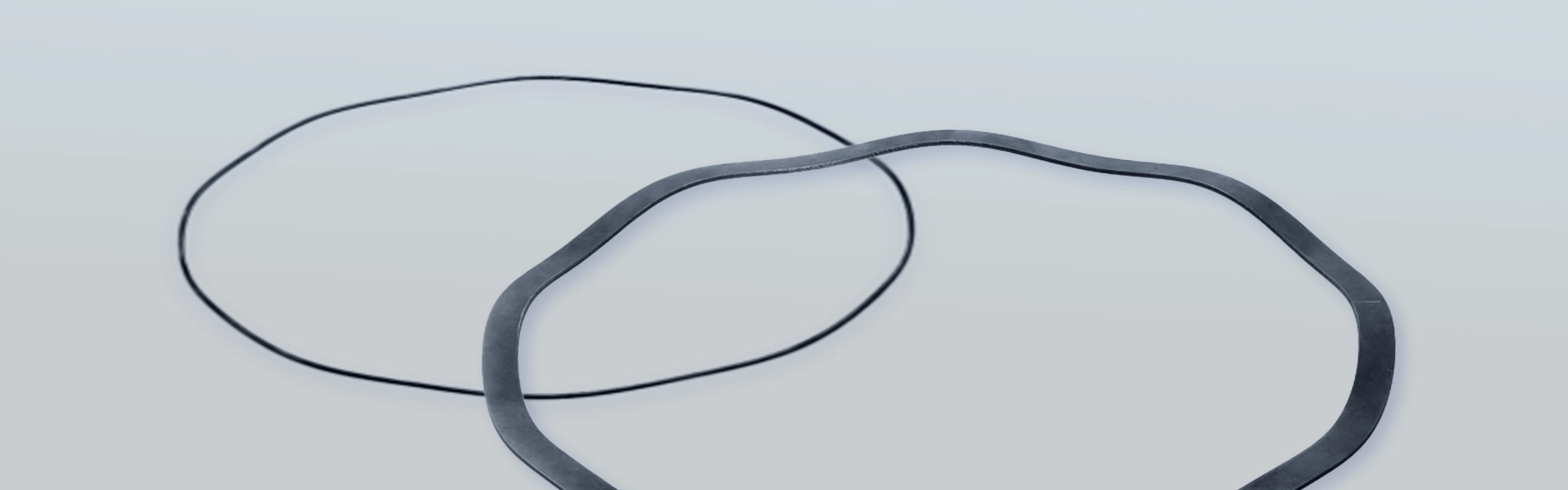

Wave springs are coiled or stamped parts/spring elements, which are usually made of flat material. They are suitable for static and dynamic areas of application.

HÄUSSERMANN wave springs are compact space-saving wonders thanks to their minimalist spring working height. With reductions in the overall height of up to 50%, they are predestined for environments that require a specification with restricted installation space. The remarkable space savings mean that assemblies can be smaller, resulting in reduced material consumption and more efficient production costs.