Not off the shelf, but rather custom-made and precisely in line with our customers’ requirements – that is HÄUSSERMANN premium quality that is becoming established around the world.

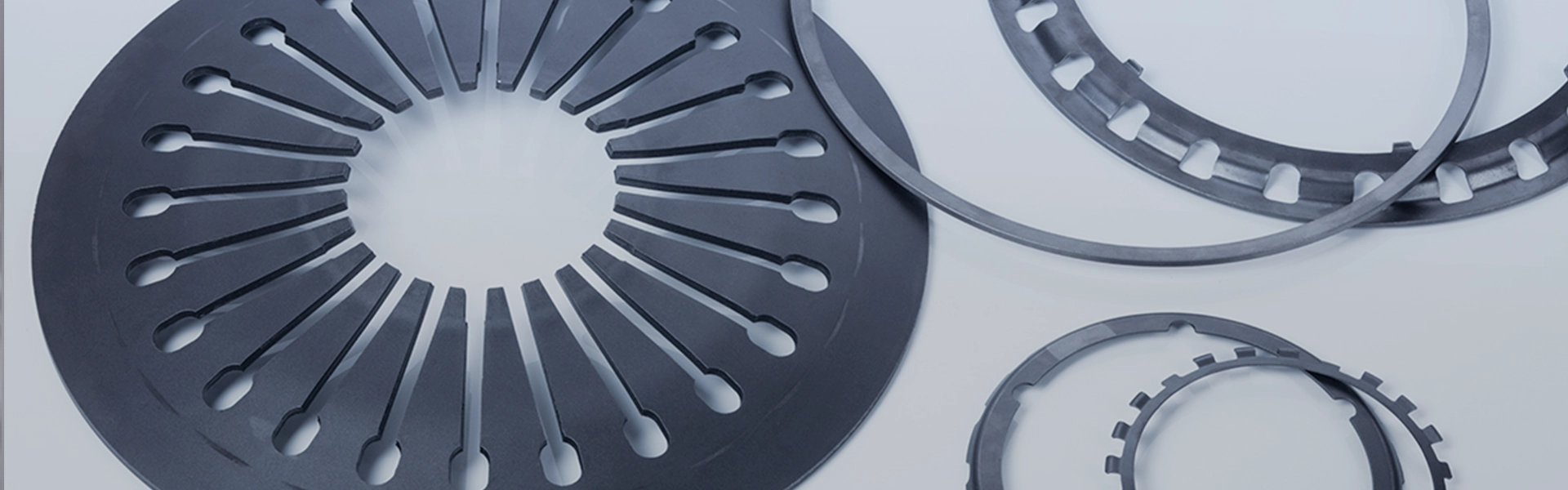

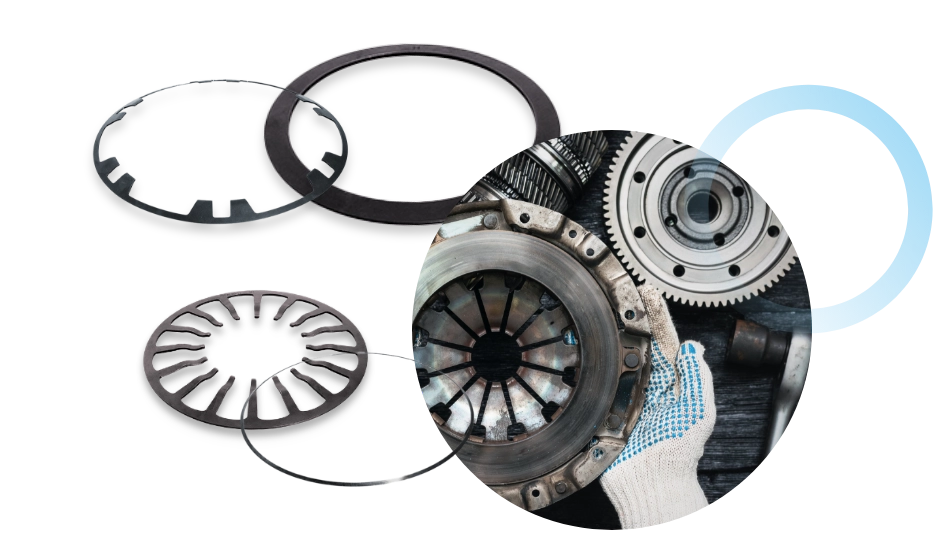

Our “customized solutions” are available in all design variants, a wide range of geometries, individual characteristics, spring deflections, power densities, overall heights, and diameters from 60 to 800 mm. As a result, the field of application of our products extends well beyond what you are familiar with from DIN manufacturers. And our IATF 16949 certified solutions can be found in industries with extreme quality requirements.

We use high-end engineering with precision to meet your requirements in terms of force, travel, installation space, performance, and service life for each individual product. From prototypes to batch sizes of 1 to 2 million.

We are the specialists for large springs, develop solutions together with our customers, and produce on our own machines built for us with special manufacturing processes. This enables us to achieve outstanding life performance of our products with narrow force tolerances and high fatigue strength.

Throughout the entire development process, application advice plays a key role for a permanently safe high-end solution that sets standards.

Materials that can withstand a lot

Standard materials (C75S and 51CrV4 – established in the market as standard by HÄUSSERMANN), corrosion-resistant materials in different variants (e.g. X10 CrNi 18-8, X7 CrNiAl 17-7), coating processes and special materials such as steels for higher temperatures (X22 CrMoV 12-1, X39 CrMo 17-1), as well as chromium-vanadium steel 50CrV4 according to EN 10089 and EN 10132-4 and stainless steel EN 10720-2 (1.4310) are used.